The DSTV Assistant for Creo Elements/Direct allows you to easily generate NC data from various 3D file formats. Thus, you can open any STEP, SAT or other formats and convert them into the required NC data, which can then be used as a direct template for e.g. saw/drill rigs, as well as drill/burner rigs.

In addition to the largely automated creation of the DSTV NC data, the DSTV Assistant offers numerous import and export options as well as an excellent analysis of the components, which will provide you with detailed information in the event of any errors in the template and quickly lead to the solution of the problem.

The DSTV Assistant is the optimal tool for all those who work in the interface between designing and production, e.g. in the steel trade, for suppliers or your own production and for all designers who do not use SolidSteel.

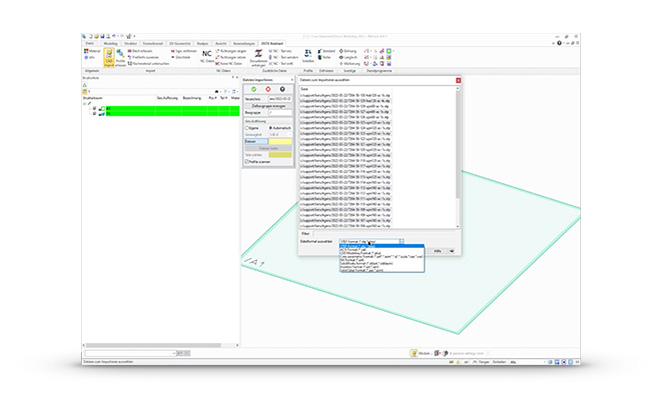

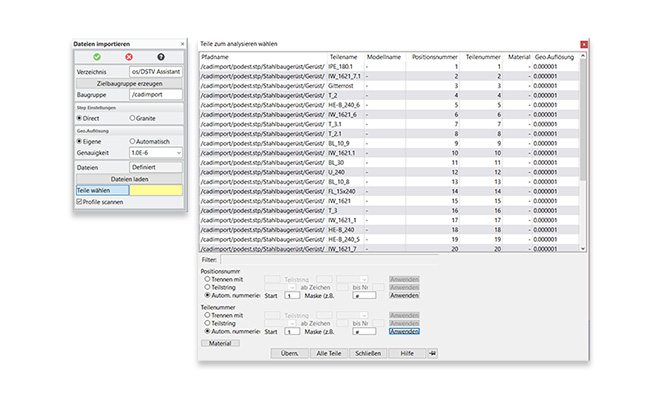

A wide range of formats are available to import data. These include the common interchange formats in the STEP or ACIS (.sat) standards, as well as PTC's own Creo E/D and Creo parametric formats, Siemens NX, SolidWorks, Inventor and SolidEdge files. Single parts or multiple parts can be inserted into a new assembly with just one step. In addition, it is possible to influence the geometric resolution during the import and to activate the scanning of existing profiles.

The import dialog of the DSTV Assistant is able to import several parts at the same time. To ensure that the parts are numbered correctly, it has an analysis function that can be used to check the file names for position and part numbers. If this information is not available, automatic number assignment can be applied.

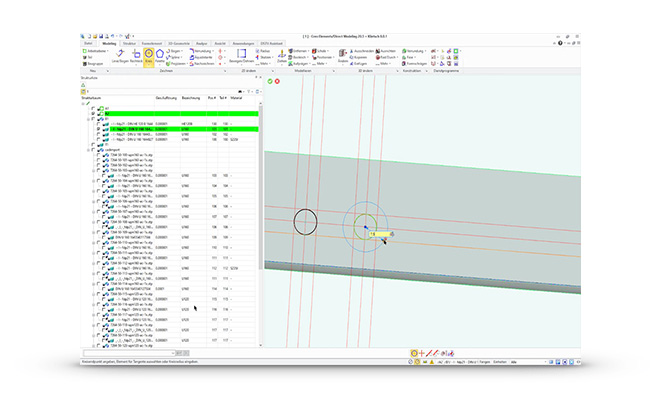

After the import, you will receive the result of the profile analysis. Both standardized rolled profiles and your own special profiles, once created in the database, are reliably recognized and correctly assigned.

It is also easy to assign materials retrospectively. For this purpose, you can easily assign a material to individual components, to all components or to all components without material specification.

The DSTV Assistant allows you to detect geometrically identical parts before exporting the DSTV NC data. To do this, select the entire assembly and start the identical parts detection. After a few seconds, you will get a summary that leads to improved job planning for manufacturing.

With the Assign Profile Info function, it is possible to subsequently correct profiles in templates that have not been designed accurately. In this way, you define the front side, longitudinal direction, profile type, etc. with just a few clicks and ensure flawless DSTV NC data.

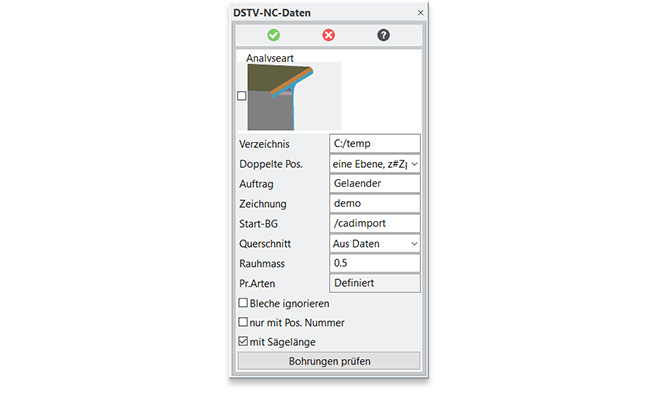

The "NC Data" menu item allows you to have complete control over the what, how and where of the export. Another useful option is the "Check bores" button. This function checks whether the bores are perpendicular to a surface, since machines usually only accept this type of operation. This way, if the program detects diagonal drilling, you will know about it before any problems arise in the manufacturing process.

The analysis of the NC data was performed simultaneously with its generation. You can see the result in the form of a tabular overview, so that you can directly see whether the export was error-free or not. If not, you can click on the error icon to get more information that will help you to fix the problem. To prevent the unintended use of erroneous NC data, it is not saved for faulty components.

In an ideal world, such problems would not occur, but in practice, unfortunately, you often have to deal with them. One solution would be to contact the manufacturer of the templates, describe the problem, and request an error-free template. This process is correct, but consumes a lot of time and therefore money. Fortunately, DSTV Assistant provides you with an accurate error report so that the error can be found quickly.

The benefits of Creo Elements/Direct as a direct modeling CAD software come into play in such cases. You don't have to write an e-mail to the customer to ask him to repair the faulty machining of the template. Instead, with just a few steps, you can do the repair yourself in a short amount of time. This is faster than writing to the customer and ensures smoother operation on the shop floor.

The function for recording sheets also makes it possible to set basic parameters such as designation, standard and the material of the component. The documentation layer for possible labeling on the front or back side can also be defined here. Only the front side needs to be selected as the reference surface. After this is done, the DSTV Assistant analyzes the geometry of the part and automatically determines the orientation of the axes and more.

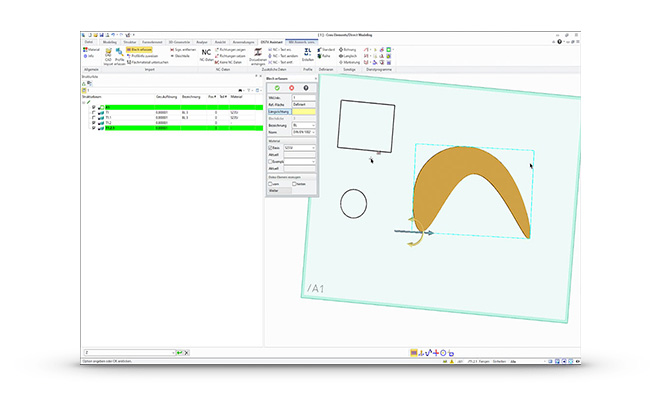

Free forms, which normally only occur with sheet metal, can be converted into polylines with the help of the DSTV Assistant. The maximum deviation from the spline curve is defined via the coarseness settings in the "NC Data" dialog and thus the number of points/lines is determined. The points are set dynamically, so that there are few points in slightly curved lines and more points in sections with greater curvature. In this way, an optimized NC code is obtained without losing control over the resolution of the freeform.

It is possible to easily add powder lines, free text and the like by using documentation layers. The software supports you in this. All you have to do is select the surfaces on which these edits are to be made, and the DSTV Assistant automatically creates the necessary work plane.

It is even easier to automatically add labels, such as position numbers or other information. These standard texts can be defined via the settings in the NC defaults. All you have to do is define the desired parameters, such as job number, position number, font and size, and the position on the part once. Then this data is automatically added to the DSTV NC data records.